In power electronics, the ability of insulation materials to withstand high voltages is a decisive factor for the safety and longevity of electrical systems. Our High-Voltage Stress Generator (HVSG) was developed precisely for this purpose – to test materials under extreme conditions.

Due to the high risk of electrical hazards, the HVSG may only be operated as part of an extended system network with a secure enclosure and a safety system.

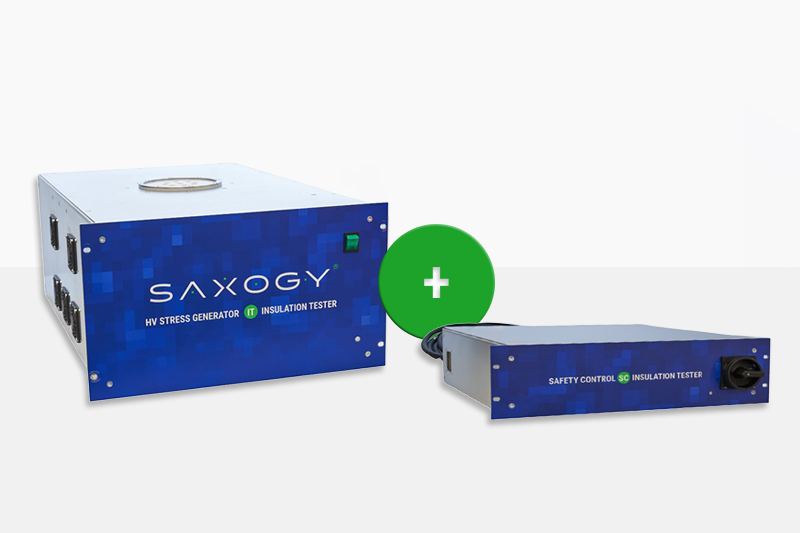

Accordingly, we have developed a multi-stage complete system (see HVSG Extended), which includes the following main components:

- High-Voltage Stress Generator and the

- Safety system with the Safety Control Box and peripheral safety components such as control element, signal column and guard locking, and

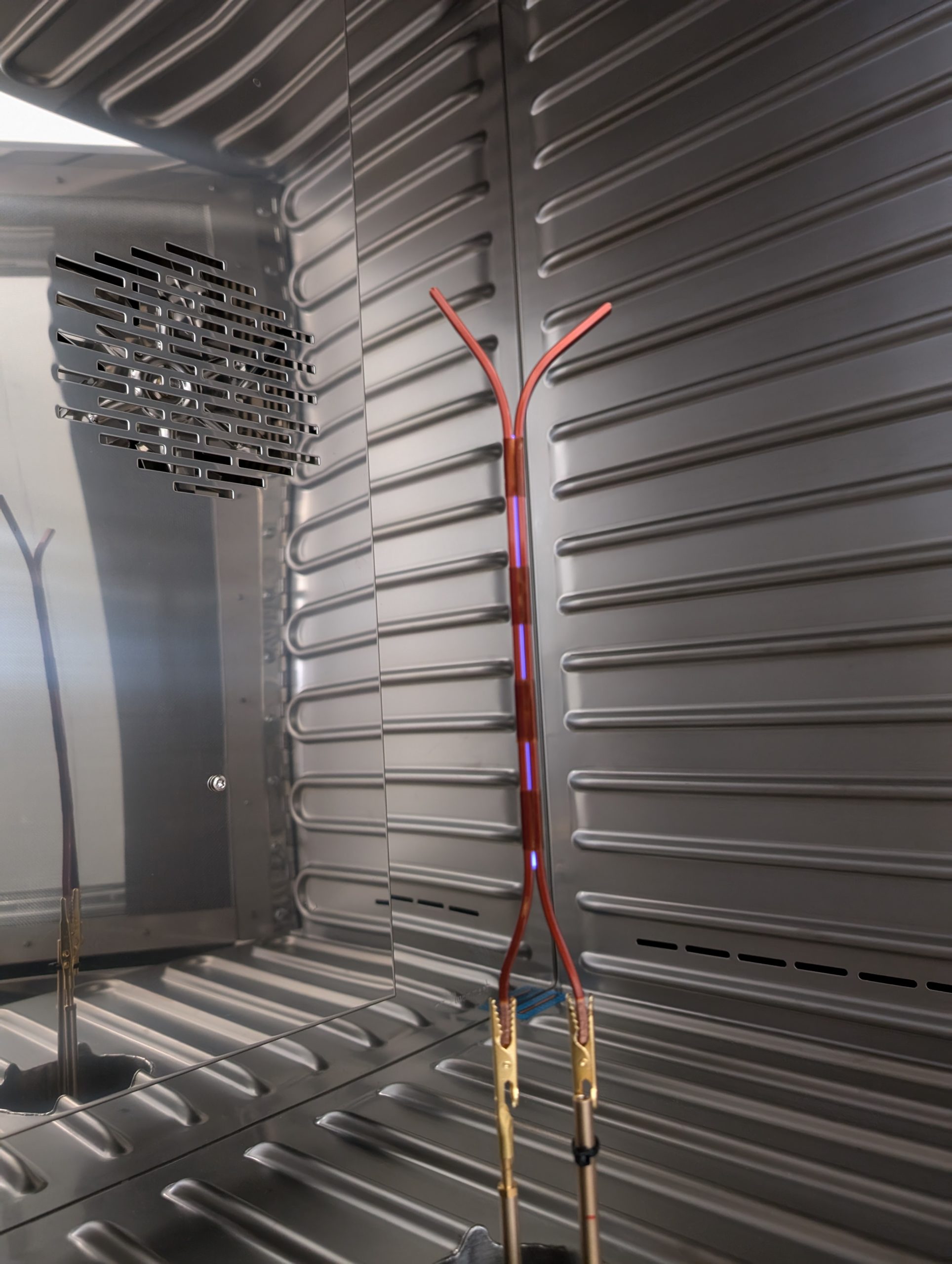

- the test cabinet with DUT (devices under test) holder.

Technical highlights:

- Bipolar voltage pulses from 0.4 kVₚₚ to 12 kVₚₚ

- Adjustable voltage slope up to 200 V/ns

- Robust short-circuit shutdown

- Customised DUT holder

- Choice between manual and automatic operating modes

Areas of application:

- Research, development, quality assurance – wherever high-voltage components and insulation materials need to be tested reliably.

Suitable for common testing standards:

- IEC/TS 61800-8:2010

- IEC 60034-18-41:2021

- IEC 62068:2013

- IEC TS 63263 ED1

- IEC 60851-7

- GB/T 4074.21-2018

After two years of development, our dU/dt generator was presented for the first time at PCIM 2024 and in the trade press. You can find more information on this in our blog.

The HVSG – three versions, one technology: Standard, Safety, Extended.

Our High-Voltage Stress Generator (HVSG) is available in three modular versions – tailored to different requirements: from the stand-alone solution HVSG Standard to the safety-optimised premium version HVSG Safety to the fully integrated complete system HVSG Extended.

Standard

(Stand-alone)

Safety

(HVSG + Safety Control Box1)

Extended

(Complete system + peripherals and integration)

Technical details

Adjust. square-wave frequency

1 kHz- 20 kHz

1 kHz- 20 kHz

1 kHz- 20 kHz

Rise times (Customisable)

50ns – 200ns

50ns – 200ns

50ns – 200ns

Number of adjust. gradients

16

16

16

Max. voltage amplitude

+/-6000V

+/-6000V

+/-6000V

Min. voltage amplitude

+/-200V

+/-200V

+/-200V

Short-circuit shutdown

Integration of passive RL networks

upon request

upon request

upon request

Integrated measurement technology

–

Integrated dU/dt measurement (software)

–

Unlocking generator output

Unlocking HV-Source

–

Emergency stop

–

Guard locking of test chamber

–

Yes (interface)

Integrated safety PLC

–

Multiplexer (up to 8 DUTs parallel)

–

Oven up to 250 °C

–

–

Ozone extraction

–

–

upon request

Prüflingsaufnahme

–

–

customisable

DUT holder

PL d (PL e)

PL e

PL e

Power supply

230 V AC 1/N/PE

Pmax = 1.2 kW

230 V AC 1/N/PE

Pmax = 1.2 kW

230 V AC 1/N/PE

Pmax = 1.2 kW

Communication

MODBUS TCP/IP

MODBUS TCP/IP

MODBUS TCP/IP

CE

1The Safety Control Box (SC Box) is a central component for integrating the HVSG into a safe test situation. The SC Box is installed in a 19″ housing and is located in the rack and below the HVSG. The SC Box is switched on via a rotary switch on the front. The SC Box is operated via a control element, the supply and control interfaces lare ocated on its rear side.

As our premium solution product in the field of power electronics, the High-Voltage Stress Generator (Extended) combines state-of-the-art technology, the highest safety standards, and maximum performance.

Thanks to its modular design, the HVSG is fully customizable and can be tailored precisely to individual testing requirements—including the following options:

- Oven integration for temperature testing up to 250 °C

- Multiplexer for parallel control of up to 8 DUTs (devices under test)

- Ozone extraction for safe test environments

- Flexible test item holders for different material and geometry requirements

The High-Voltage Stress Generator (Extended) offers maximum flexibility, scalability, and safety—a tailor-made, high-end solution for demanding tests of future insulation systems in power electronics as well as rotating machines, transformers, cables, and bearings.